Home>Outdoor Storage>10 Best Telescopic Ladders for DIY Projects Around the House

Outdoor Storage

10 Best Telescopic Ladders for DIY Projects Around the House

Modified: December 6, 2023

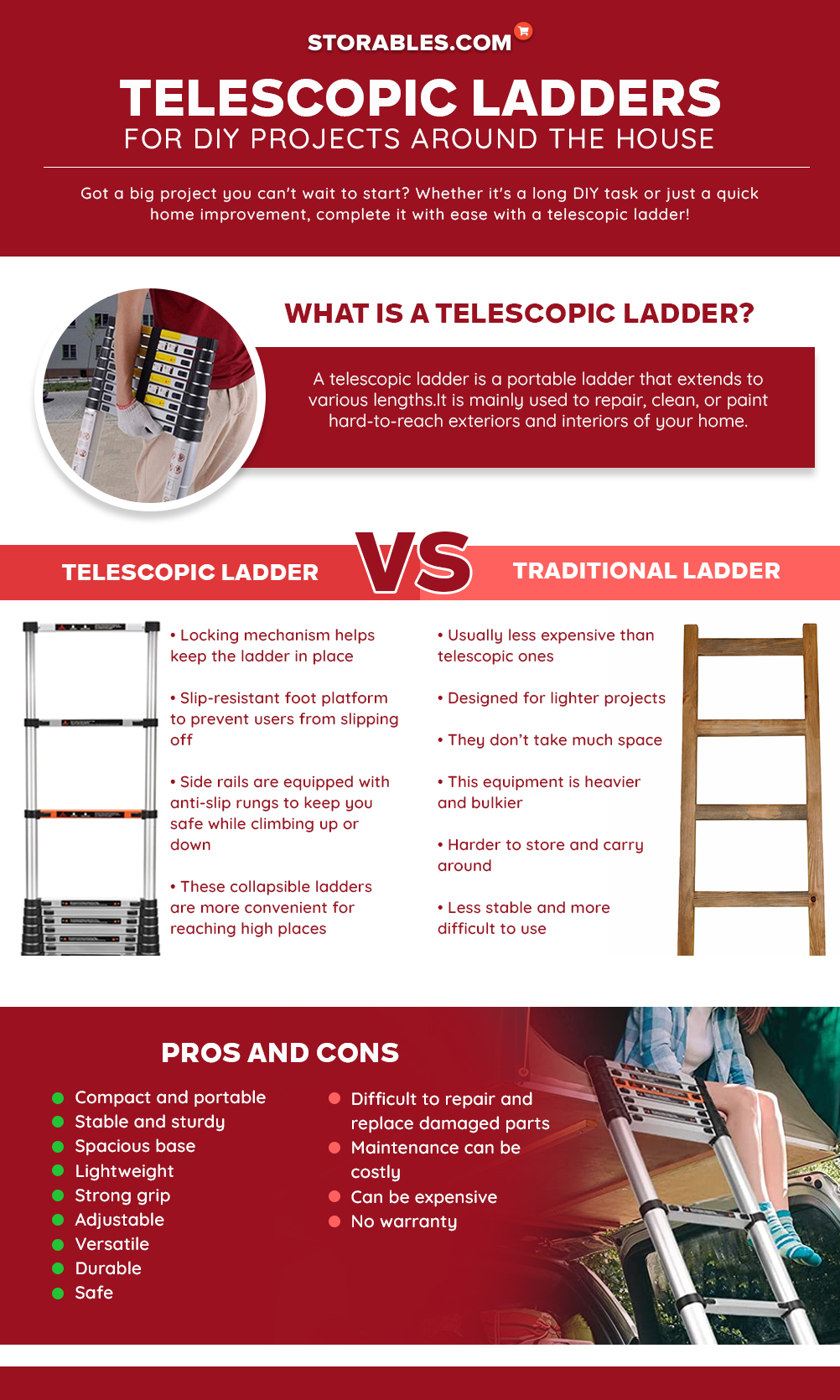

Got a big project you can't wait to start? Whether it's a long DIY task or just a quick home improvement, complete it with ease with a telescopic ladder!

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Everybody loves a good do-it-yourself (DIY) project. They are simple, inexpensive, and a creative way to showcase your personality. For some, a DIY home improvement project is an opportunity to upgrade their interior and exterior decor without breaking the bank. However, the success of expanding your DIY horizon relies on many factors, and tools are no exception. Luckily, a telescopic ladder is here to save the day!

What Is a Telescopic Ladder?

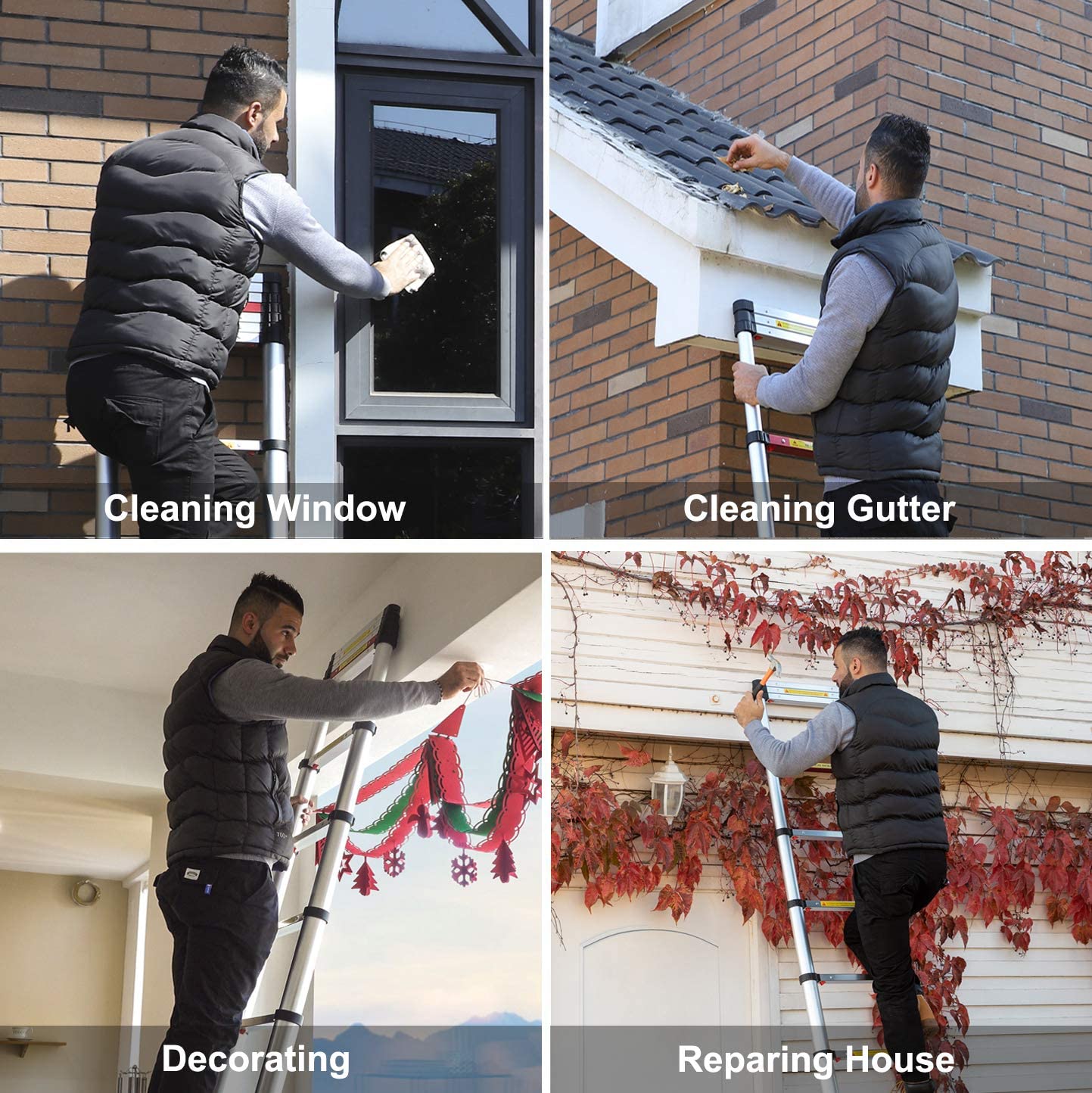

A telescopic ladder is a portable ladder that extends to various lengths, depending on your needs. It is mainly used to repair, clean, or paint hard-to-reach exteriors and interiors of your home. However, they’re also helpful for other home projects and quick fixes, such as installing bathroom shelves, reorganizing display racks, and mounting overhead hooks in the garage.

Most telescoping ladders are retractable to a more compact size and come with a carrying strap. This feature will help you carry them around without straining your back and shoulders and is convenient for those with limited storage space.

Read more: What Is A Telescopic Ladder

Telescopic Ladder vs. Traditional Ladder

Telescopic extension ladders offer several features to ensure the user’s safety. For example, the locking mechanism helps keep the ladder in place without needing additional support, while the added weight capacity provides more support to a broader range of consumers. They also have a slip-resistant foot platform to prevent users from slipping off and getting into other accidents.

Furthermore, the side rails are equipped with anti-slip rungs to keep you safe while climbing up or down. With a simple push of a button or by moving the rungs, these collapsible ladders are more convenient for reaching high places. This makes them more versatile compared to many other ladders.

On the other hand, traditional ladders are usually less expensive than telescopic ones since they’re designed for lighter projects. In addition, they don’t take much space. However, this equipment is heavier and bulkier, making it harder to store and carry around. They’re also less stable and more difficult to use, which can be dangerous if you’re not accustomed to using them.

Why Use a Telescopic Ladder?

Telescopic ladders are an excellent choice for DIY enthusiasts and professional contractors who need security and convenience while working on a wide range of projects. This equipment has a solid built quality and doesn’t wobble when in use. Moreover, they are completely portable and fold up quickly, fitting in most cars or trucks without compromising your traveling space.

These ladders also feature extra-long rungs and wider treads that make you feel comfortable several feet up from the ground. So if you’re looking for a reliable tool to help you with your home DIY projects, you should consider getting a telescopic ladder.

Pros

- Compact and portable

- Stable and sturdy

- Spacious base

- Lightweight

- Strong grip

- Adjustable

- Versatile

- Durable

- Safe

Cons

- Difficult to repair and replace damaged parts

- Maintenance can be costly

- Can be expensive

- No warranty

What to Look For in a Telescopic Ladder?

Choosing the right one can be confusing. Here are some tips to help you decide which ladder is best before investing one for your home.

Size

When buying a telescoping ladder, ensure that the measurement fit all your requirements. The length of your ladder will depend on the type of project you’re working on. For example, there is no point in purchasing a ladder that is too short if you plan on installing ceiling storage in your home. Fortunately, most telescoping ladders can extend up to 20 feet, giving you more options.

Read more: How To Use Telescopic Ladder

Material

A telescopic ladder should be made of high-quality materials, including aluminum or steel, to ensure your safety and the equipment’s durability. The materials used for its construction should also resist rust, corrosion, and cracks for long-lasting use. Additionally, the ladder must have sturdy construction to avoid bending and accidents when it is extended or while in service. The ladder’s feet should also have a sturdy frame and tight joints to prevent swaying or wobbling while planted on the ground. Furthermore, check if the ladder is made with anti-slip steps with strong grips on rungs for an extra layer of support to prevent you from falling off while in use.

Height and Weight Capacity

Most telescopic retractable ladders can carry up to 330 pounds, which means they can support you and any item you carry while accomplishing your task. However, it’s always best to check the maximum weight capacity before purchasing to ensure you get the right equipment. Furthermore, a folding ladder’s minimum human height requirement is 6 feet. Some models, however, allow you to work up to 10 feet tall, making them ideal for taller individuals or those who need extra support when performing heavy tasks. The maximum ladder height is usually 20 feet, but this depends on the model and the manufacturer, so always take note of this information before buying.

Best Telescopic Ladders for At-Home DIY Projects

Whether you’re working on a simple DIY home project or need one for commercial use, these all-around telescopic collapsible ladders will surely fit your needs.

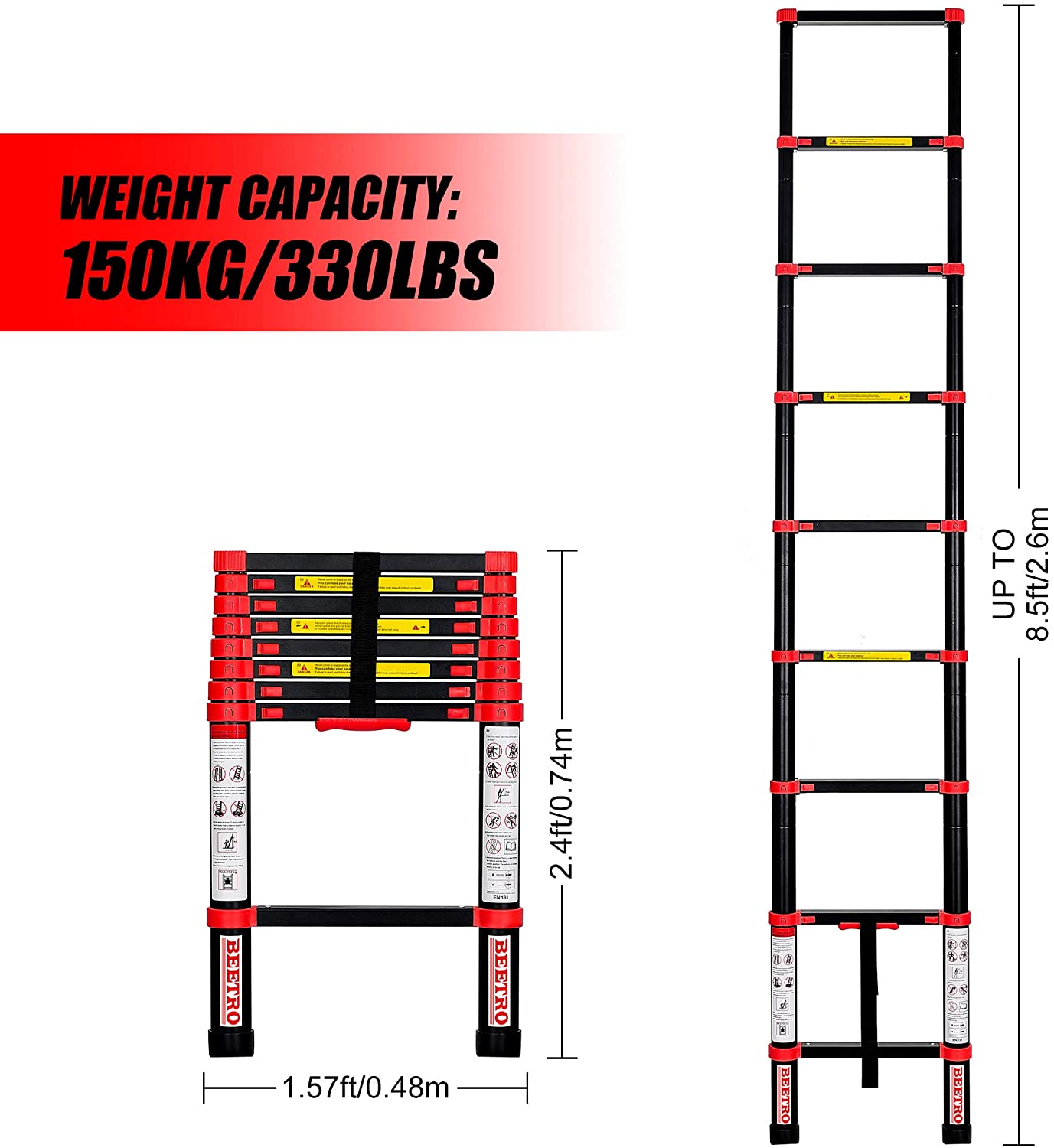

Whether you’re trying to clean the top of your RV, are changing some light bulbs, or just working on a project around the house, the BEETRO folding ladder will help you reach these sections with ease. This durable equipment made from aluminum is enough to support up to 330 pounds. It also comes with a non-slip cap that gently creates friction on the surface floor, keeping it stable. Furthermore, its lightweight design ensures portability and ease of use, while its slide latches provide safe storage when it’s not needed.

Key Features

- Reaches up to 8.5 feet

- Extension and retraction design

- Has slide latches

- Has strengthening footboard

- Non-slip cap

Specifications

- Product dimension: 31 inches x 18.9 inches x 3.4 inches

- Product weight: 13.42 pounds

- Material: Aluminum

- Load-bearing capacity: 330 pounds

Pros

- Maneuverable

- Stable

- Sturdy

- Portable and space-saving

Cons

- Limited height reach

- May need more force to close or fold

Mishandling a telescopic ladder can quickly lead to property damage, serious injuries, and accidents. Luckily, the RIKADE portable ladder has an independent button adjustment and safety lock buttons for each section to ensure secure climbing and precise extension. It also has double hooks and non-slip feet covers for better stability, so you don’t have to worry about tipping over or sliding to the ground. Moreover, this retractable ladder has a maximum weight capacity of 330 pounds, perfect for heavy-duty tasks. It is also lightweight, ideal for carrying around for home use, construction sites, and even camping trips.

Key Features

- Reaches up to 10.5 feet

- Independent button adjustments

- Anti-slip foot cover

- Stable double-hook

- Safety lock button

Specifications

- Product dimension: 32.5 inches x 19 inches x 3.7 inches

- Product weight: 20.8 pounds

- Material: Aluminum

- Load-bearing capacity: 330 pounds

Pros

- Sturdy structure

- Portable and compact

- Convenient hand grip

- Wide and sturdy rung

Cons

- Height may be limited for some projects

- Can be costly

This telescoping loft ladder from DICN is equipped with anti-slip rubber feet and a rubber sleeve on every step to make climbing more accessible. The height extends to 10.5 feet, ideal for working around most residential buildings or single-story houses. It’s also made with corrosion-resistant aluminum alloy, making it durable. Additionally, the ladder comes with securing straps and a grip handle for added portability.

Key Features

- Reaches up to 10.5 feet

- Anti-slip rubber feet

- Rubber sleeve

- Securing straps

Specifications

- Product dimensions: 32.28 inches x 19.29 inches x 3.54 inches

- Product weight: 20.2 pounds

- Material: Aluminum

- Load-bearing capacity: 330 pounds

Pros

- Affordable

- 1-year full warranty

- Portable and compact

- Ideal for most single-story residential homes

Cons

- The mounting bracket is sold separately

- The ladder may bend past the 9-feet mark

- Rungs may fall abruptly, causing injuries

Ladders are essential for any home or workplace, especially for projects of great height. Therefore, when choosing the best equipment, safety should be on top of your list. That’s where the BOWEITI Telescoping Extension Ladder comes in.

This telescopic extension ladder is crafted from aluminum alloy and reinforced materials giving you maximum strength and longer service life. Furthermore, its impressive range of 12.5 feet provides convenience, especially for hard-to-reach areas of the house. This telescoping ladder also features an ample size top cap, which offers safety and stability to users.

Key Features

- Reaches up to 12.5 feet

- Enhanced thickening buttons

- Reinforced materials

- Longer service life

- Upgraded materials and accessory

Specifications

- Product dimensions: 52.3 inches x 28.5 inches x 6 inches

- Product weight: 30.3 pounds

- Material: Aluminum

- Load-bearing capacity: 660 pounds

Pros

- Sturdy

- Easy to store

- Lifetime technical support

- Includes a carrying bag, user manual, and work gloves

Cons

- Bulky

- The top cap may come off easily

If you’re looking for a telescopic extension ladder with a convenient multi-function design, the ALPURLAD is for you. This ladder can be extended from a compact 4.5 feet to an impressive 12.5 feet in height, giving you the flexibility to reach more areas in your home. Additionally, the product features a durable and stable design, with non-slip feet for added security on any surface.

The ladder is also made of anti-corrosion aluminum alloy, which is more durable than iron and steel, making it suitable for any indoor or outdoor use. This 12.5 feet extension ladder also comes with a waist bag for easy access to tools and equipment when working. Furthermore, all other parts are assembled using high tenacity nylon plastics and have anti-skid treatment steps to ensure safety and stability when in use.

Key Features

- Reaches up to 12.5 feet

- High tenacity nylon plastic

- Anti-skid treatment steps

- Thick non-marking aluminum tube

- Multi-lock design

Specifications

- Product dimensions: 18.6 inches x 2 inches x 34.6 inches

- Product weight: 21 pounds

- Material: Aluminum, bamboo-derived rayon

- Load-bearing capacity: 330 pounds

Pros

- Multifunctional

- Space-saving

- Has a laser-printed lock reminder

- Comes with a tool waist bag

Cons

- Heavy

- The top cap may come off easily

If you’re planning on taking up serious DIY home projects, the HogoR’s Xtend & Climb 785P+ Pro Series is your guy. This heavy-duty telescoping ladder offers up to 15.5 feet of height and retracts 36.5 inches for easy storage and transport. It also features an aerospace-engineered aluminum alloy structure that provides strength and durability to carry out any task. Additionally, the angled thumb release ensures proper hand position when climbing up or down, while the clean touch anodized finish gives this ladder a sleek look that’s easy to clean.

Key Features

- Reaches up to 15.5 feet

- Heavy-duty

- Aerospace engineered

- Double over-molded feet

- Angled thumb release

Specifications

- Product dimensions: 36 inches x 19.74 inches x 4.5 inches

- Product weight: 37.5 pounds

- Material: Aluminum

- Load-bearing capacity: 250 pounds

Pros

- Great for professional use

- An integrated carrying handle for transportation

- Can be safely used with a ladder jack

- Sturdy and maneuverable

Cons

- Expensive

- Quite heavy for a telescopic ladder

- No angled rungs

- Safe working height limits at 12.5 feet mark

Accomplish any home project with ease and convenience with this premium telescoping ladder from GIMYFY. Each step of this versatile product is equipped with a double height-locking latch to ensure safety and stability while in use. Moreover, the high-quality aluminum alloy material comes with an anodized surface for a more durable and sturdy frame. It also comes with a removable project tray to help carry your construction tools and equipment while at work.

Key Features

- Reaches up to 15.5 feet

- Anodized finish

- Anti-pinching double height-locking latch

- Convenient project tray

- Slip-resistant rung

Specifications

- Product dimension: 38.98 inches x 19.37 inches x 3.86 inches>

- Product weight: 31 pounds

- Material: Aluminum

- Load-bearing capacity: 330 pounds

Pros

- Smooth adjustment

- Compact and portable

- Extra stability

- Versatile

Cons

- Quite heavy

The WolfWise telescoping ladder is the perfect solution for RV campers and homeowners looking to do all maintenance, repairs, and DIY home improvements. This extension ladder features a one-button retraction that helps prevent injuries while assembling and disassembling. Additionally, it has a shatter-proof bumping design equipped with air-damper technology, making the item crash-resistant as it descends slowly to its compact size. It is also equipped with a stabilizer bar and a non-slip mat to give you a comfortable grip while on it.

Key Features

- Reaches up to 15.5 feet

- Air-resistant technology

- Proprietary locking system

- Stabilizer bar and a non-slip mat

- One-button retraction

Specifications

- Product dimensions: 19.2 inches x 1.96 inches x 39.37 inches

- Product weight: 35.3 pounds

- Material: Aluminum

- Load-bearing capacity: 330 pounds

Pros

- Shatter-proof

- Multifunctional

- With a heavy-duty strap for portability

- 2-year warranty

Cons

- Quite heavy

If you’re looking for a self-supporting ladder ideal for any home improvement project, consider this telescoping ladder from Hihone. This ladder can be fully extended up to 16.5 feet and folded into an 8.3 feet A-frame for your quick ceiling and window repair needs. The quick button retraction feature allows safe access to the top rung, while the finger-safety adjustment protects you from injuries.

Moreover, its corrosion-resistant construction keeps this ladder sturdy and firm, while the rubberized on-slip end cap helps prevent your fingers from slipping off during use. Furthermore, this item has an automatic locking function that can be quickly released with just one hand and an anti-slip lightweight design that prevents bending or breaking.

Key Features

- Reaches up to 16.5 feet

- Adjustable to 8.3 feet A-frame

- Quick button retraction

- Finger-safety adjustment

- Corrosion-resistant

Specifications

- Product dimensions: 37.25 inches x 19.25 inches x 7 inches

- Product weight: 22.4 pounds

- Material: Aluminum

- Load-bearing capacity: 300 pounds

Pros

- Sturdy

- Rubberized non-slip end cap

- Automatic locking

- It has a shock-absorbing strap between the rungs

Cons

- May be shaky near the top

The Jupiter Telescoping Ladder is a multipurpose ladder that offers 20 feet of fully extended reach and a 330-pound capacity. It also comes with two detachable hooks for more secure climbing, especially in high places. Furthermore, the anti-slip foot pads secure your balance while performing other tasks using both hands. The independent locking buttons on each rung also increase safety while climbing, preventing hand jamming and other injuries.

Key Features

- Reaches up to 20 feet

- 2 detachable hooks

- Multipurpose ladder

- 16 steps with a 15-inch distance

Specifications

- Product dimensions: 18.9 inches x 42.9 inches

- Product weight: 36 pounds

- Material: Aluminum

- Load-bearing capacity: 330 pounds

Pros

- 2-year warranty

- Prevents hand injury

- It has a higher reach

- Portable and sturdy

Cons

- Can be pricey

- Quite heavy

Basic Ladder Safety

To help you use your telescopic ladder safely, here are a few essential safety tips to keep in mind:

Gear and Location

Always wear proper gear such as gloves and goggles to prevent cuts and scratches on your hands or eyes. This will also protect your body from debris, chemicals, and other materials that might fall while on the ladder. Another thing to be vigilant of is the ground beneath you. Place your telescopic ladder on a solid surface free of litter or loose materials to prevent accidents and injuries. This will also prevent uneven pressure on the ladder, which may damage your equipment.

Inspect Your Equipment Before Using It

Before using a telescopic ladder, ensure that all parts are secure, intact, properly aligned, and adequately locked to avoid accidents. In addition, always check for cracks and rusts that can affect the ladder’s performance during operation. Finally, ensure that the ladder base is appropriately planted on the ground before moving up or down.

Be Careful

Always place one foot at a time on each rung while going up or down to avoid losing balance and falling off from higher levels. Additionally, avoid touching the locks while you’re up there as you may accidentally release them, causing severe injuries to yourself and others around you. Furthermore, most of these retractable ladders have reminders that indicate when you’re already climbing too high. Make sure to follow these warning signs for your safety.

Be Gentle With the Ladder

Forcing your ladder to close, open, or extend can quickly damage the equipment. Instead, make sure that you follow the instructions in the manual to enjoy its lifelong service. Moreover, ensure that the ladder is locked and stored in a safe, dry place when not in use to avoid any unnecessary wear and tear.

Conclusion

While there are various types of ladders to choose from nowadays, a folding ladder exceeds all expectations with its effortless, effective, and safe features. So, whether you are working on a steep surface, an emergency repair, or taking up a DIY home renovation, consider investing in this equipment to give you the reach you need to complete your project.

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “10 Best Telescopic Ladders for DIY Projects Around the House”